Ugolini Macchine per tintura

Benvenuto nel mondo Ugolini

Ugolini srl è stata fondata nel 1974 da Umberto Ugolini, dopo una lunga esperienza presso ILMA di Schio (Vicenza),azienda leader nel campo dei macchinari tessili.

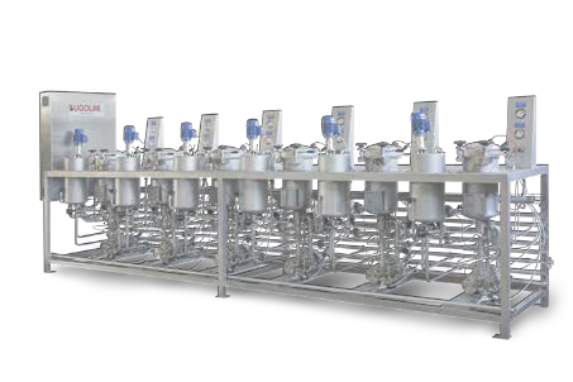

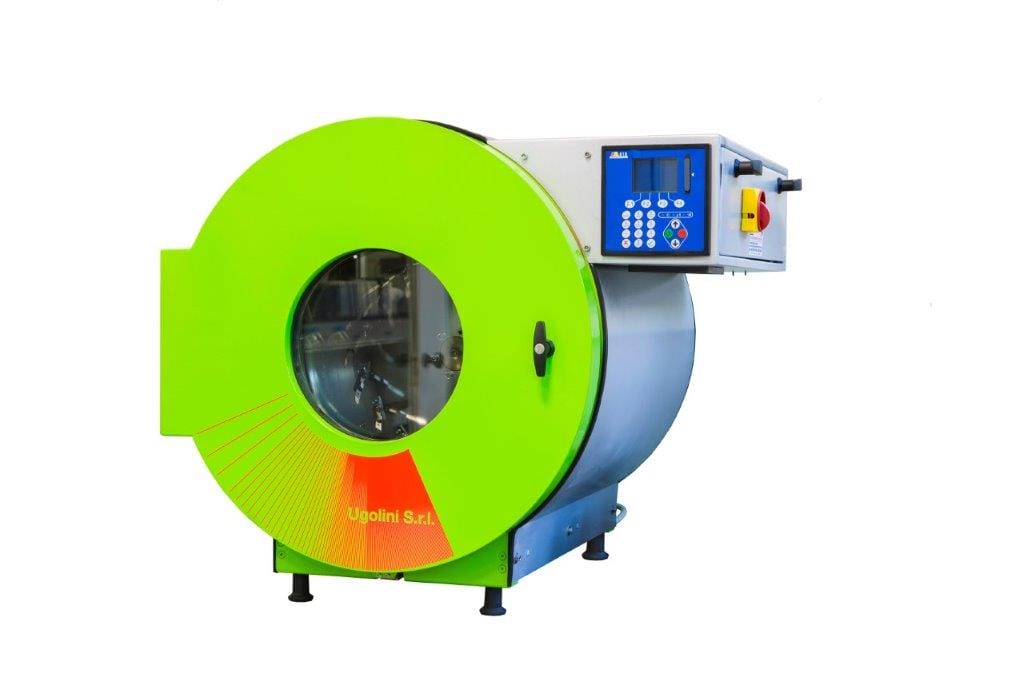

Oggi Ugolini srl offre alle ditte tessili di tutto il mondo la sua vasta gamma di prodotti che comprendono quattro principali tipologie di produzione: macchine per tintura, macchine da laboratorio, macchine per finissaggio, accessori inox per tintoria.

Ugolini srl gestisce completamente le fasi di progettazione e produzione: le attività principali sono in effetti integrate all’interno dell’azienda, a garanzia della qualità costante dei propri prodotti e del rispetto dei tempi di consegna.

Le macchine vengono progettate e costruite seguendo i più svariati standard: PED, ASME STAMP, TUV, ANFOR, SELO, etc.

ESPERIENZA ED AFFIDABILITÀ

Macchinari per tintoria, Ugolini: la qualità italiana

Precisione, Durata, Innovazione

L’industria italiana dei macchinari per tintoria è rinomata in tutto il mondo per la qualità dei suoi prodotti.

Ugolini si distingue per l’attenzione ai dettagli, l’uso di materiali di alta qualità e l’applicazione di tecnologie innovative. I prodotti Ugolini per l’industria dei macchinari per tintoria sono noti per la loro affidabilità, durata nel tempo e prestazioni eccellenti.

Ugolini collaborando con i più grossi gruppi tessili mondiali è riconosciuta e apprezzata in tutto il mondo per la qualità e l’affidabilità delle sue macchine per tintoria.

Ugolini ha ottenuto importanti omologazioni e certificazioni, come PED e ASME per gli Stati Uniti, TUV per la Germania, ANFOR per la Francia e SELO per la Cina, confermando l’eccellenza dei suoi prodotti.

I prodotti made in Italy nel settore dei macchinari per tintoria rappresentano l’eccellenza italiana nel campo, soddisfando le esigenze dei clienti a livello globale e contribuendo alla reputazione di qualità e prestigio dell’industria italiana.

Servizio Clienti

Tutte le macchine ugolini sono molto affidabili. Per ogni problema si assicura sempre un’assistenza tempestiva con visita diretta o da remoto.

Vengono forniti interventi da remoto grazie ai software che permettono ai tecnici di monitorare il funzionamento della macchina in ogni fase ed operazione in modo da poter fornire un’assistenza online, in tempo reale.

Ugolini rivolgendo una particolare attenzione al mercato internazionale garantisce l’assistenza tecnica grazie alla presenza di tecnici presenti in ogni Paese del mondo. È inoltre attiva una linea diretta

Macchine Ricondizionate

Ricondizioniamo tutte le macchine usate Ugolini e macchine di tintura a filo da laboratorio e produzione usate usando componenti meccanici, elettronici e di sicurezza, più avanzati tecnologicamente.

Ogni macchinario viene quindi fornito di tutte le documentazioni tecniche nella lingua del cliente. Le macchine sono completamente preparate collaudate e garantite, pronta per essere poste in servizio.

Certificazioni internazionali

News

DTG Textile & Garnment 2024 | Dhaka (Bangladesh)

VISITA IL SITO DELLA FIERA 23-25 JANUARY 2024 Dhaka – BANGLADESH Hall 8 – Booth 042

COLOMBIATEX 2024

VISITA IL SITO DELLA FIERA 23-25 JANUARY 2024 MedellÍn – COLOMBIA PABELLÓN AMARILLO | STAND AM210-A

Le nostre macchine tintura tessuti alla DTG 2023, Dhaka – Bangladesh!

La fiera Dhaka International Textile and Garment Machinery Exhibition si tiene ogni anno in Bangladesh per presentare le novità internazionali riguardanti i settori di Macchine confezione tessile, Tessuti per la casa, Industria Tessile. Il nostro referente Mohammad Satil introduce Simplex, uno dei nostri macchinari per la tintura a filo appositamente progettata per avere una riproducibilità […]

L’arte incontra la realtà aziendale: le residenze d’artista.

Quando l’arte interagisce con le nostre vite porta sempre con sé innumerevoli benefici. Quando l’arte interagisce con il lavoro, che occupa la maggior parte del nostro tempo, e si interseca alla realtà aziendale, non può non essere promotrice di innovazione, cultura e nuove prospettive. Abbiamo avuto l’onore e la soddisfazione di essere stati citati dal […]