Minisimplex

Air cushion laboratory machine

Minisimplex 20/150 GR

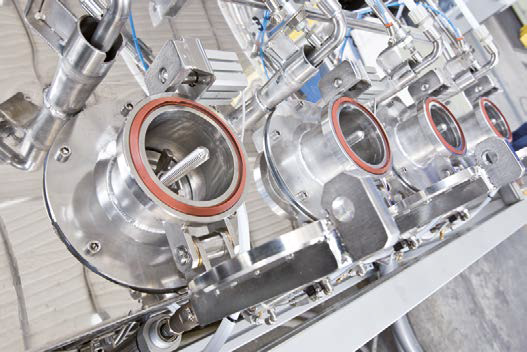

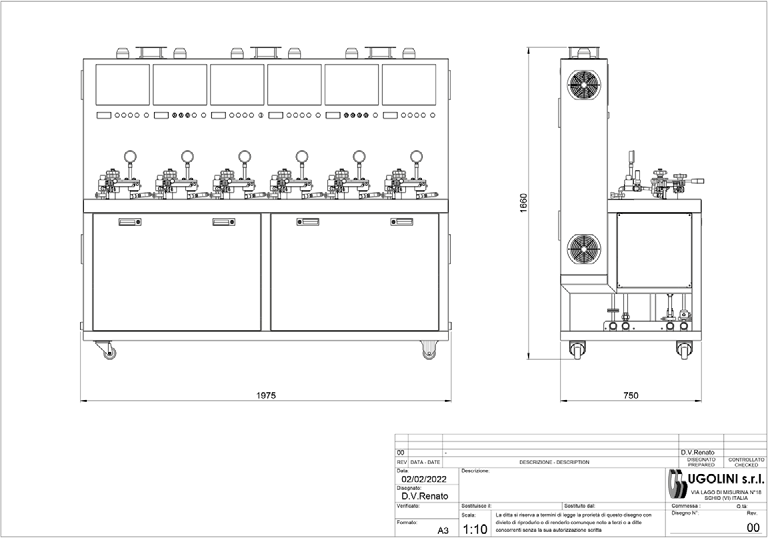

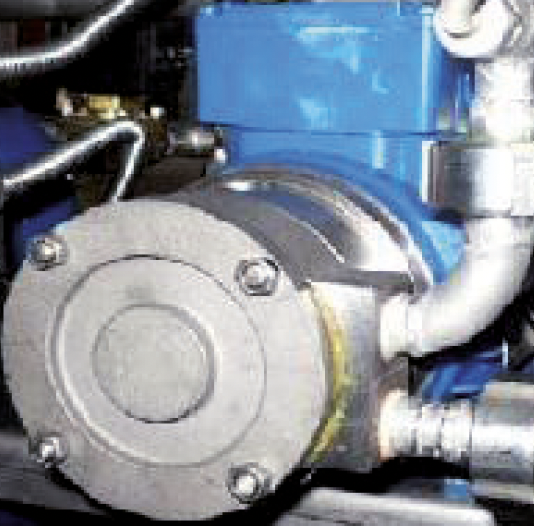

The main feature of this machine, working in air pad mode, is to maximize the reproducibility of samples from the laboratory to the production, with excellent flexibility and perfect color quality. The machine can be from one to 10 kiers and each kier has its own pump and its own temperature probe, so each process is independent from the other.

It is ideal for creating new recipes while saving yarn or fabric and at the same time using the same process as production machines.

Dye any type of natural or synthetic substrate in high density pkg, fabrics, ribbons, fiber. The pkg is wrapped in a perforated stainless steel tube using a special laboratory winder.

The machine is made in stainless steel Aisi 316 L and works with air pad system, with automatic regulator. It is equipped with 6 bar mechanical safety valve, pressure switches and safety thermostats, proximity sensor on the lid, pressure gauge and thermometer in front of kier.

Dimensions: internal diameter and working height useful for dyeing from 25 to 120 gr with a liquor ratio from 1: 5 to 1.12.

Automatic filling level, normal and high temperature drain, overflow rinsing.

Electric heating with long-life resistors or steam heating, water cooling. Both electric and steam heating in the same machine are avaiable as option.

The product tank, if present, has all the automatic dosing and flow back functions and can be heated and mixed and is automatically rinsed.